Sustainability + Product Life Cycle

Designing furniture has environmental impacts, let’s face it. As does the design and manufacture of most products. Materials are consumed, supply chains and manufacturing processes are employed and from the time the product makes its destination for end usage, there will be maintenance and end of life impact.

There are a lot of critical factors in the manufacturing process when it comes to sustainability that as a business we take seriously and review on a regular basis. Below we touch on a few of the key aspects that have been a real focus for us as a business of late.

Materials:

Buying in materials is a daily affair for us as a manufacturer. Therefore choosing what materials, what supply companies to work with and working with designers and clients on this is a very important part of our business function.

- The board for our tables and workstations

- Laminate selections

- The foam within our chairs

- The glue that is used to bind elements together

- Down to the paint we choose for our powder-coating line

- Even the location of where those materials come from

Product Quality and Product Life Cycle:

We were recently approached by a client to review existing products that had been used on a work floor for over 10 years. The client asked us to see what we could do with a set of products in terms of upgrading them so they could be re-used. Our Maxton Fox team took the pieces back to the factory to review how we might be able to update them. By adding additional and updated components, and freshening up the products we gave those pieces an additional life span of 5 – 10 years, without making a new set entirely from scratch.

As a manufacturing organisation that controls the making process locally, we are able to review our product quality first hand. We are also able to work with clients on existing products and how we might be able to re-work them.

Quality is a first priority for us at Maxton Fox. So much so, there are three real project cases of quality of manufacture that our products have lasted the test of time and are still being used to this day.

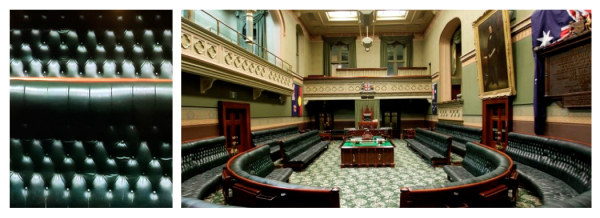

NSW Legislative Assembly Chamber

In c. 1974 we (the Founders of Maxton Fox) won their first NSW Government Contract. The project involved manufacturing and upholstering all of the seating within the Chamber as part of the restoration project. Diamond Button detailed leather upholstery was adopted to cover the seating which you can still see today. This project that was 45 years ago, and the team have not received one phone call about product fault or fix based on the quality of the goods. This seating is still in tact and being used on a daily basis.

Qantas Gate Lounge Seating

Back when it was TAA (Trans-Australian Airlines) in the 80s we (pre-Maxton Fox) were awarded the Gate Lounge Seating contract throughout domestic airport lounges in Australia. TAA then became Qantas Airlines. Lounge seating that was manufactured by us in Sydney, Australia is still being used to this day, on a daily basis, at Qantas Domestic Lounges in various airports in Australia namely Sydney, Brisbane, Melbourne and Adelaide. Airport lounges as you can imagine receive a high amount of usage, all hours of everyday. To see our seating still standing is testament to our manufacturing capability and product quality. Some of the seating has more recently been re-upholstered and upgraded to leather instead of fabric, and this is something we pride ourselves on as an organisation in being able to re-work existing quality frames, such as this airport seating.

RiverCat (InCat) Ferry Seating

Ever travelled in Sydney on the RiverCat Ferry? If so, then it’s also likely you have sat in one of our chairs. The Head Product Engineer at InCat (no longer operating as a business) experienced our Qantas seating and wanted exactly that chair design for a fleet of InCat ferries worldwide. We won this contact due to our R&D capability even back in the 80s. We re-engineered the airport seating to reduce the weight of the frame significantly, where weight was an extremely important consideration in the shipping / ferry business. Our seating is still being used on these Ferry’s located in Sydney, China, France, Tasmania.

If sustainability is on your agenda then selecting to work with a manufacturer that builds product that last the test of time is fundamental to achieving your sustainability goals. It also goes without needing to say that choosing a local operator is naturally a sustainable choice.

So, get in touch with the team at Maxton Fox today for your next project!